3D printing

Detail drawing

Advantages

| 3D PRINTING RAPID PROTOTYPING |

| Prototype manufacture comes early in the product development cycle. |

| Early visualization of design and manufacturing problems |

| Materials used are expensive or toxic |

| Design of jigs, fixtures etc. not required for prototype manufacture |

| Prototypes are build directly from its CAD model |

| Materials used are brittle |

| A very few tests are carried out |

| Design changes are not costly |

| Product development cycle time is drastically reduced |

| Rapid prototyping is agile |

| Easy to convert 3D-CAD model to prototype |

| Made of ABS, plastics, plastomers, metals etc... |

| Very short lead time |

| Difficult to produce Complex designs |

Packaging & delivery

Packaging Details

Plastic molds packing methods:

1-Painted with anti corrosive paint to protect the mold from rust

due to the heavy humidity on sea

2-Wrapped with plastic film to protect the mold from rust due to

the heavy humidity on sea

3-Load on very strong durable poly-wood boxes

4-Loading container for sea shipping

Remark:since mold it self is very heavy,unless mold is very small

Port:Shanghai/Ningbo/Shenzhen/Other Sea Port In China

Delivery time: 7 to 10 days by DHL ,Fedex, UPS,TNT etc, carton box or crate are avaiable.

|

Item name |

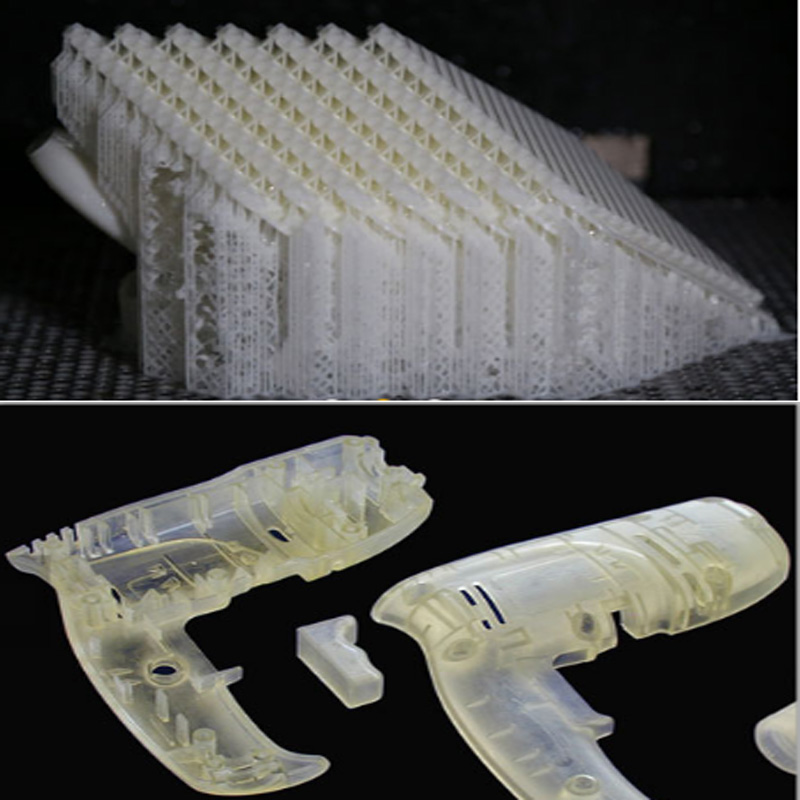

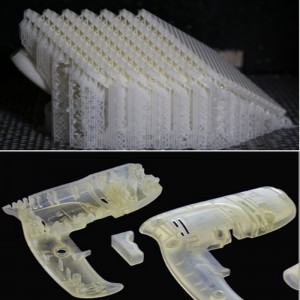

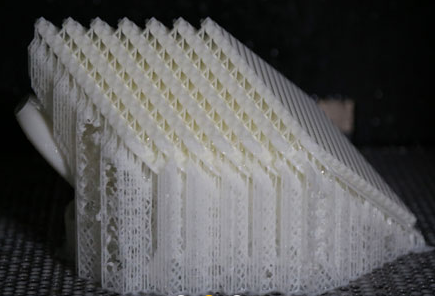

Factory 3d print sla prototype plastic resin nylon 3d print prototyp sla 3d printing service |

|

Sevices |

1.CNC machining;2.3D printing;3.Silicone Mold & Vacuum Casting;

4.Surface finishing & painting; 5.SLA & SLS prototyping; 6.Sheet metal fabrication; 7.RIM (reaction injection mold); |

|

Available format |

igs/.stp/.x_t/.step/.prt/.stl/.sldprt/.dwg/.dxf |

|

Material |

1.Metal: copper/stainless steel/Aluminum(6061/7075)/Etc2.Plastic:

• ABS-(Natural / Black / Flame Retardant/) • PC / Polycarbonate-(Clear / Black) • ABS+PC-(Clear / Black) • PMMA / Acrylic- (Clear / Black) • PA/Nylon-(Natural / Black / 30%GF) • PP / Polypropylene-(Natural / Black / 20% GF) • POM / Acetal / Delrin-(Black / White) • PPS / Polyphenylene sulfide • PVC/ Polyvinyl chloride (White/Gray) • PTFE/ Polytetrafluoroethylene • PEEK/ Polyether ether ketone • Epoxy Tooling board |

Packaging & delivery

1-Start from part design analysis

2-3d printing service for rapid prototyping,as well as CNC machining for rapid prototyping

2-Mold design drawing and DFM report available so you can see how is the mold going to be before mold making

3-If product is complex,mold flow report will be present as well

4-In house mold making shop ensure you mold quality under well control.

5-Normally it takes 20-40 days to make mold,precise time depends on part design

FAQ

Factory.

We can make all kinds of plastic injection molds, but we are very good at the production of food packaging molds such as thin-wall container, bucket.

Yes.

Yes.

CAD,UG etc.

Generally it is 35-65 days.

Yes, We will provide samples to our customers after the first molds trial by free.

We have great R & D department and strict quality control department. We will design and manufacture all kinds of molds according to customer's requirements.