Injection Molding

-

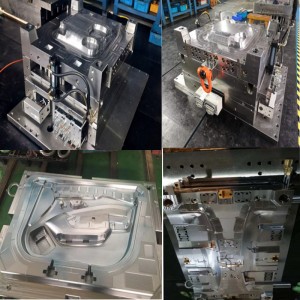

OEM ODM Custom Plastic Injection Molding Tooling Injection Plastic Mold Rapid Prototyping and Tooling Service

Company Name Shanghai Jinyili Molding Technology Co., Ltd. Business Type Manufacturer Main Product Plastic injection mold,Medical part mold,IML/IMD,2K injection mold,Silicone rubber mold,Die casting,Prototype,CNC Milling, CNC turning… File Format Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,Sample Plastic Material HIPS ABS, PC, PP, PS, POM, PMMA,PE,AS,PPSN,PBT,PA66,PC/ABS.etc Moulds’ lead time 20-35days,it depends on the product’s size and structure Bulk production lead time 25-30days,it depends on the product’s size and structure Product’s weight range 1g to 5000g Mould Precision +/-0.01mm Mould Life 300k-500K shots,update moulds for free Mould Cavity Single cavity, multi-cavity. Runner System Hot runner and cold runner. Equipment 1.Tooling Development Machinery : Swiss Mikron High Efficiency Machining Center, Swiss Mikron High Speed CNC Machining Center,Japan Makino CNC Milling Machining Center,Taiwan Well Head CNC Machining Center,Swiss Charmilles EDM Machining Center,Japan Makino EDGE 3S Sinker EDM…2.Component Finishing Machinery: Henghui Sing & Bio-Padding Machine,100,000 Grade Oil Spraying Line… 3.Injection Machenery: TOYO Fully Electric Injection Molding Machine Si-Five,YIZUMI Injection Machine,DONGHUA Injection Machine,HAITIAN Machinery,SUMITOMO Injection Machine,HAITIAN Double Molding Machine… Injection machies equipments According to product precision to choice the different model 80T,120T,250T,450T,800T,1200T injection machine. Surface Treatment Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture, Sanblasting,Gilding, UV Painting… Color White, black, red, blue..et. according to customer’s requirement. Inspection 100% inspection by QC, QA before shipping. Applications All kinds of cars spare part , machinery, home appliance, electronic products, medical devices, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts,and more. Quality Control System ISO9001 quality management system certification; Package According to customer’s requirement Place of Origin Shanghai, China Product Material Plastic Material Aluminum, plastic, copper, brass, galvinized etc. Size Customized Surface treatment Powder coating, eletroplating, oxide,anodization Technics Turning, Milling, CNC center Application Appliance, Auto, Building, Capital equipment and etc Sample Need to pay sample fee OEM Accept Drawing Format 3D/CAD/Dwg/IGS/STP Color Customized Packaging and delivery Packaging Details Inner pearl button, outside carton box, or customized. Port Shanghai port Supply Ability 500000 Piece/Pieces per Year -

Plastic injection moulding Customized/OEM High Precision Metal Stamp Stamped Stamping Part for Car/Automobile/Mac

Automotive thermal management series

Company Name Shanghai Jinyili Molding Technology Co., Ltd. Business Type Manufacturer Main Product Plastic injection mold,Medical part mold,IML/IMD,2K injection mold,Silicone rubber mold,Die casting,Prototype,CNC Milling, CNC turning… File Format Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,Sample Plastic Material HIPS ABS, PC, PP, PS, POM, PMMA,PE,AS,PPSN,PBT,PA66,PC/ABS.etc Moulds’ lead time 20-35days,it depends on the product’s size and structure Bulk production lead time 25-30days,it depends on the product’s size and structure Product’s weight range 1g to 5000g Mould Precision +/-0.01mm Mould Life 300k-500K shots,update moulds for free Mould Cavity Single cavity, multi-cavity. Runner System Hot runner and cold runner. Equipment 1.Tooling Development Machinery : Swiss Mikron High Efficiency Machining Center, Swiss Mikron High Speed CNC Machining Center,Japan Makino CNC Milling Machining Center,Taiwan Well Head CNC Machining Center,Swiss Charmilles EDM Machining Center,Japan Makino EDGE 3S Sinker EDM…2.Component Finishing Machinery: Henghui Sing & Bio-Padding Machine,100,000 Grade Oil Spraying Line… 3.Injection Machenery: TOYO Fully Electric Injection Molding Machine Si-Five,YIZUMI Injection Machine,DONGHUA Injection Machine,HAITIAN Machinery,SUMITOMO Injection Machine,HAITIAN Double Molding Machine… Injection machies equipments According to product precision to choice the different model 80T,120T,250T,450T,800T,1200T injection machine. Surface Treatment Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture, Sanblasting,Gilding, UV Painting… Color White, black, red, blue..et. according to customer’s requirement. Inspection 100% inspection by QC, QA before shipping. Applications All kinds of cars spare part , machinery, home appliance, electronic products, medical devices, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts,and more. Quality Control System ISO9001 quality management system certification; Package According to customer’s requirement -

Custom Plastic Injection Molding Injection Plastic Moulds Products Plastic Injection Parts Precision Cnc Machining Service

Place of Origin Shanghai, China Product Material Plastic Material Aluminum, plastic, copper, brass, galvinized etc. Size Customized Surface treatment Powder coating, eletroplating, oxide,anodization Technics Turning, Milling, CNC center Application Appliance, Auto, Building, Capital equipment and etc Sample Need to pay sample fee OEM Accept Drawing Format 3D/CAD/Dwg/IGS/STP Color Customized Packaging and delivery Packaging Details Inner pearl button, outside carton box, or customized. Port Shanghai port Supply Ability 500000 Piece/Pieces per Year Automotive thermal management series Company Name Shanghai Jinyili Molding Technology Co., Ltd. Business Type Manufacturer Main Product Plastic injection mold,Medical part mold,IML/IMD,2K injection mold,Silicone rubber mold,Die casting,Prototype,CNC Milling, CNC turning… File Format Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,Sample Plastic Material HIPS ABS, PC, PP, PS, POM, PMMA,PE,AS,PPSN,PBT,PA66,PC/ABS.etc Moulds’ lead time 20-35days,it depends on the product’s size and structure Bulk production lead time 25-30days,it depends on the product’s size and structure Product’s weight range 1g to 5000g Mould Precision +/-0.01mm Mould Life 300k-500K shots,update moulds for free Mould Cavity Single cavity, multi-cavity. Runner System Hot runner and cold runner. Equipment 1.Tooling Development Machinery : Swiss Mikron High Efficiency Machining Center, Swiss Mikron High Speed CNC Machining Center,Japan Makino CNC Milling Machining Center,Taiwan Well Head CNC Machining Center,Swiss Charmilles EDM Machining Center,Japan Makino EDGE 3S Sinker EDM…2.Component Finishing Machinery: Henghui Sing & Bio-Padding Machine,100,000 Grade Oil Spraying Line… 3.Injection Machenery: TOYO Fully Electric Injection Molding Machine Si-Five,YIZUMI Injection Machine,DONGHUA Injection Machine,HAITIAN Machinery,SUMITOMO Injection Machine,HAITIAN Double Molding Machine… Injection machies equipments According to product precision to choice the different model 80T,120T,250T,450T,800T,1200T injection machine. Surface Treatment Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture, Sanblasting,Gilding, UV Painting… Color White, black, red, blue..et. according to customer’s requirement. Inspection 100% inspection by QC, QA before shipping. Applications All kinds of cars spare part , machinery, home appliance, electronic products, medical devices, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts,and more. Quality Control System ISO9001 quality management system certification; Package According to customer’s requirement -

Precision injection mould

Plastic injection bucket moulding high quality inject molding mold maker factory

Description

1. Professional manufacturer/Service

2. Waterproof&Scratch-off

3. Various shape, design and size as customer require

4. Certification: ISO9001, SGS, CTI, ROHS

5.Manufacturer: over 20 years production experience

6.Low Price, High quality, Durable, Fast Delivery